CO2 and Kenaf

CO2, kenaf, climate change, pollution, economic development, new careers, more profit for corn soy and cotton farmers and ROI are some real benefits all rolled into one plant solution. Why refer to it as CO2Kenaf? Because kenaf is the leader in this while it grows and also in a product made from it called kenafcrete. Kenaf sequesters more car bon than other plants. Kenafcrete can sequester carbon for 100s of years. It continues to do so while it continuously cures, many years into the future.

10-15 tons of carbon sequestered per acre while it is growing is substantial and looking at how easily it can be introduced to our existing corn, soy and cotton farmers as a rotational cash crop we're off to a good start on handling climate change , reducing pollution, providing a resource for local economic development and new careers, additional profit for our farmers by reducing input costs and increasing yields and long term ROI for investors. How Farmers Can Get Paid. Update must see video. Video

Did you know that you can earn additional income capturing CO2 while growing kenaf or applying regenerative farming practices? Check out these documents Overview Benefits Principles

Latest CO2 Technology

Remote measuring CO2 on farmland is available now. Measuring progress on a global scale while discovering ways you can participate in this global challenge of carbon sequestration and affect climate change. Regen Network

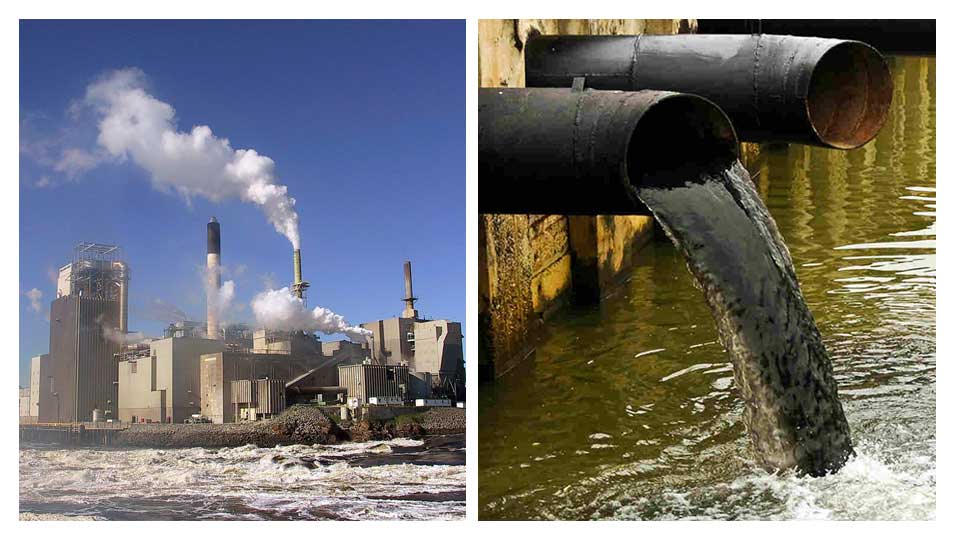

CO2 and Other Pollutions in the Field

Let's take a closer look at how kenaf can address pollution on site (in the field).

This is the list of where most on site pollution occurs:

- The use of fossil fuels emissions from tractors and transportation vehicles.

- The extraction, processing and distribution of fossil fuels for tractors and transport vehicles should also be considered.

- Erosion pollutes our waterways and is also a loss of "soil capital".

- Fertilizers that are washed away by rain and irrigation into our waterways and seep into our aquifers where well water is polluted. Lakes and rivers are where most municipalities get their water and this polluted water needs to be treated before we use it.

- The extraction of fertilizers is very destructive and leaves the environment degraded and toxic.

- Pesticides also pollute the soil, air and our waterways.

- Herbicides pollute soil, air and water.

- Tilling releases CO2 from the soil which pollutes as well and contributes to climate change.

- Drain tiles used in commercial farming addresses flooding only,is costly and current tiles are made of a plastic derived from fossil fuels.

The list of how kenaf can reduce most pollution on site:

- The use of kenaf seeds as a source for bio-diesel reducing fossil fuel pollution by lowering transportation costs and environmental destruction through fossil fuel extraction processes that also release CO2.

- Kenaf is known to remediate soil and can remove heavy metals and other toxic substances from soil.

- Current industry fertilizers are not needed when growing kenaf preventing this form of pollution getting into our waterways and water sources.

- Pre-emergent weed control (herbicides) only needed initially before planting where cover crops are not used. This reduces the quantity used and the pollution through the supply chain.

- Pesticides are not needed when growing kenaf.

- Kenaf is drought tolerant and can reduce the amount of water needed substantially.

- Keyline plowing can be used in place of drain tiles by contolling water flow that would normally result in flooding, store water throughout a crop field in the soil for when and where your crops need it.

Pollution in Industry

Rather than going through a via of carbon credits let's see how we can handle industry pollution directly with kenaf. It is possible to do this while providing a superior resource, lower costs and locally acquired, while transitioning methods and stakeholders in the supply chain.

For the purpose of demonstration I'll take one of many industries from source to end product as it exists today.

It starts with the logging industry that sources our forests for its' wood used in both wood and paper products. Wood products like particle board(kenaf is the superior resource for particle board in Japan) and wood pellets. Paper products including toilet paper, copy paper, envelopes, mailers, cardboard and packaging material.

In the paper industry, kenaf because of it's color, requires less bleach reducing pollution with lower quantities getting into our water ways. Better yet hydrogen peroxide can be used in place of bleach and the output into our waterways become H2O instead of bleach.

Since kenaf over time can produce 4-5 times more wood per acre than a forest, the need to cut down trees in our forests would be reduced. This leaves more of our forests in tact to contribute to removing CO2 as well.

Transitioning logging companies to processing and transporting kenaf wood and fiber to their customers who use trees for wood and fiber has additional benefits besides saving our forests and sequestering more CO2. Logging companies connecting with local corn, soy and cotton farmers who grow kenaf as a rotational cash crop can reduce the number of miles traveled and reduce overall costs. New local markets can pop up benefiting farmers, loggers, entrepreneurs and local communities.

Logging companies could additionally contract with farmers instead of contracting only with federal and state forests and property owners.

Economic Development and New Careers

This may be obvious, but I feel it should be mentioned so it is not overlooked. Adding kenaf as a rotational cash crop on existing corn, soy and cotton fields, which has over 25,000 uses provides abundant opportunities in the communities where it is grown, processed and manufactured products. See what I mean with "Unlocking The Mysteries of Kenaf".

More Profit For Corn, Soy and Cotton Farmers

Corn and soy farmers usually alternate between these 2 crops where market prices fluctuate up and down out of their control. Cotton farmers growing a single crop in the same fields year after year results in degraded soil, lower cotton quality and prices paid to the farmers.

Kenaf used as a rotational crop can benefit these farmers in several ways besides increasing their overall profit.

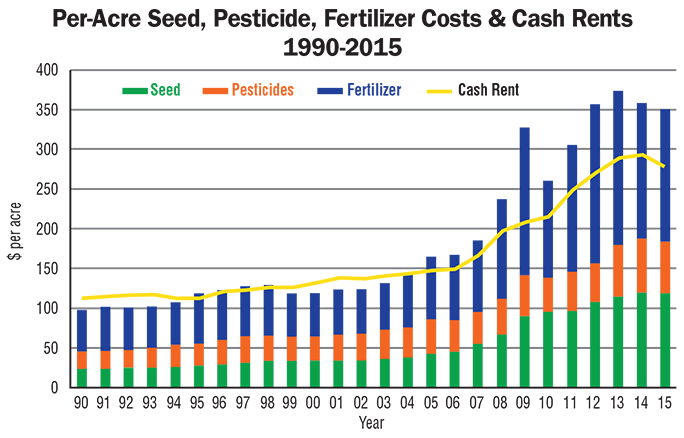

The following is just an example of costs in an everchanging industry.

Corn seed per acre at $118.00

Average costs per acre for soybean ranged from $168 to $204 and average cost per bushel sold ranged from $3.30 to $4.19. Average returns per acre ranged from $62 to $194. Better efficiency (low cost per bushel) occurs with higher yields.

Cotton growers paid $8.40 per acre for their planting seed. In 2004, 10 pounds of BtRR cotton seed cost $14.90 and growers paid an additional tech fee of $3.82 per pound, bringing the total cost for planting seed to $53.10 per acre.

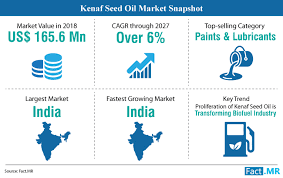

Kenaf growers pay $60.00/acre for 20 lbs. of seed for fiber/wood/seed for certain varieties. One buyer/manufacturer in Indiana pays $00.34/lb. for fiber and with yields of 5 tons/acre (or more) that is a return of $3,400.00/acre minus expenses.

Kenaf seed growing operations are reported as producing 1,000 lbs. of seed per acre and only require 20 lbs. of seed (all varieties we tested except Whitten which requires 2lbs./acre) that is $6-$60/acre at $3/lb.

Whitten has sold for $10/lb in the past and requires 2 lbs./acre because of its' 3 foot spacing.

1,000 lbs./seed/acre minimum at $3/lb. is $3,000/acre minus costs. These are very conservative estimates. With reports of much higher seed yield/acre possible, your investment in kenaf seed is likely to see higher returns.

Farmers growing kenaf as a rotational cash crop without the extra costs of seeds, pesticides, herbicides, water and fertilizer should see an increase in profits and preparing soil for higher yields in soy fields following a season of kenaf.

In addition to this, farmers could qualify for additional income from CO2 sequestered per acre just growing kenaf as a rotational cash crop. ReGen Network

ROI for Investors

Now is the time for investors to look into and plan for the emerging markets in the USA kenaf industries.